The rise of IOT in the warehousing and logistics Industry

The Internet of Things (IoT) refers to a network of connected smart devices extracting information from which businesses can get useful insights. This increased volume of available data has unlocked the potential for businesses to manage and optimise a wider range of operations, minimising costs and improving profitability. IOT is a rapidly growing trend in all industries as part of Industry 4.0 and its adoption is only predicted to continue to expand.

In the warehousing and logistics industry, pressures from increasing globalisation including foreign competition and the need for ever faster operations has meant the industry has been an early mover on this innovative technology. Applications for IOT in this industry are already embraced, be it in the way warehouses inventory is tracked or how forklifts movements are monitored. IOT is allowing sites to raise the bar on performance to levels that were unattainable in the past, making sure they can compete in the global market.

The limited use of IOT at the loading bay

One area of the industry where IOT has been underutilised is the loading bay, where its use remains limited and opportunities for improvements are large. A warehouse loading bay serves as the main point of entrance or exit for products that are loaded or unloaded from vehicles, an activity strongly connected with a warehouse’s bottom line and profitability. A lack of data around such time-consuming and essential loading bay activities and operations makes it difficult to manage the loading bay area and often signifies recurrent delays and significant monetary losses for a warehouse. It is vital that any business now consider IOT as part of their loading bay strategy and set effective KPIs to optimise performance to enable a business to stay ahead of the competition.

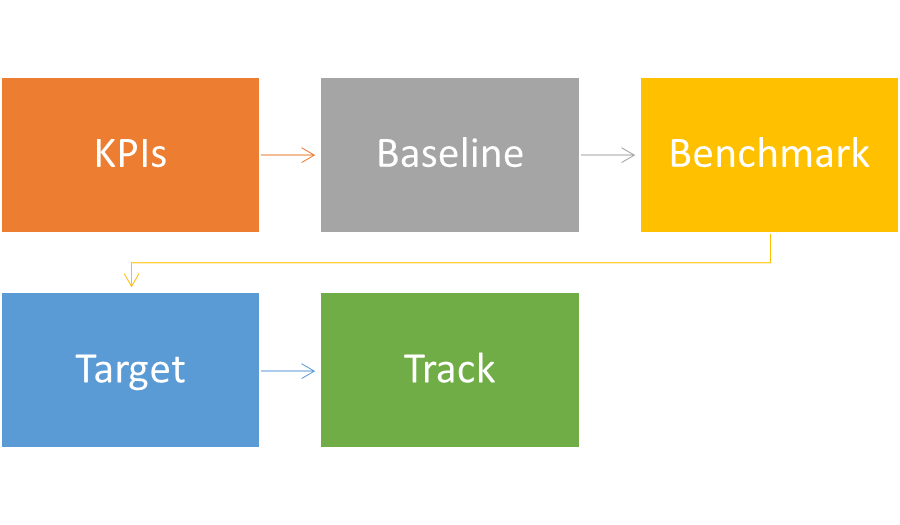

Simple 5-step guide on how to use IOT to set measurable efficiency goals for your loading bays

In the following section, we will show you how to use IOT to set measurable efficiency goals for your loading bays in 5 simple steps.

1.Choose your KPIs

For this guide the KPIs that we recommend you use for your loading bays are: bay productivity, utilisation and bay turns.

Productivity

Defined as the percentage of the load cycle spent with the bay door open, productivity provides you with an indication of how efficient you are being with your assets. I.e loading bay and employees. Productive sites increase their load capacity and reduce cost and effort, hence making them more profitable.

Utilisation

Defined as the percentage of a day spent in a load cycle, this KPI is especially important for sites that struggle or aim to increase their number of loads. Firstly, understanding site utilisation gives you visibility of how far from the maximum load capacity you are running and hence gives you an insight into what your site is capable of. Secondly, if you find large variation in bay utilsation across the site you know that you are over working some bays whilst leaving some bays to collect dust. By focusing your energy on evening out utilisation, you will boost site performance, having a happier work force and smoother operations.

Bay Turns

Defined as the number of loads that a bay completes in a day. Bay turns is a KPI worth monitoring as it allows a deeper understanding of a site’s maximum capacity.

2.Record a Baseline

Your site can’t know if performance improves unless you know where it started. This is why you first need to set a baseline for your current operations, i.e. how are you performing today? A single data point is not a baseline, that’s because of variation in anything that is measured. If your diet and exercise stays the same, your weight would vary at different points in the day and from day to day. An effective baseline needs to have several data points and needs to reflect the environment that you are setting a target for.

Traditionally this data for the baseline has been collected manually. Manual collection is limited as it is time consuming, error prone and outputs only a small reflection of how the site is performing. It is impossible to set an effective baseline for your site without true data. IOT enables you to automatically collect data on all of your bays and at any point in time.

We recommend that you collect data for 1 month to set your baseline. This should allow your baseline to cover all aspects of your loading bay operations and give you enough data to average out natural variations in bay performance and highlight outliers.

3.Find a benchmark

Through our baseline data we have a good understanding of how our site is performing, so now we need to set targets for how we want to perform in the future. The question is how do we want our loading bays to perform in the future and what is a realistic target?

This is where the importance of benchmarking comes in. Benchmarking compares the level of performance from one bay to another, typically a high performing bay. These levels can be used to set performance targets for other bays because if one bay has achieved that performance, it is easy to conceive that all bays can. This bench marking can also be done for different points in time, for example if your site performed with 70% average bay productivity for 3 days then dropped down to the months average of 50%. Your site target could be 70%, as you know you have performed at that level in the past.

A benefit of using IOT, will be the volume of data that you have at your disposal. It is important to define benchmarks for every situation e.g. different shifts and bay areas. Only then will you be setting tailored targets.

As a starting point we recommend you select benchmarks for at least three times in the day, for all three KPIs.

4.Set and Agree Tailored Targets

Now you have your benchmark it is time to set your targets. It is important to tailor targets to situations, if you don’t this can result in unrealistic expectations being set and efforts being focused on minimal impact aspects of your operations. For instance, you may have a site that is busier in the day than the night shift, and hence has more operators working that shift. If you set a blanket target of 60% productivity for all bays regardless of the time of day, you may have set a target that the night shift struggles to achieve with its lower operator number. You may end up reducing morale for the night shift employees with unrealistic targets, all the while reducing focus on the day shift where your efforts could be more rewarded for optimising the day shift.

Instead use your benchmarks to set realistic targets and agree them with the employees accountable for them. We recommend that you go through your benchmarks with your bay supervisors to come to an agreed target.

5.Make Changes and Track Results

Now that you have your targets you can make operational changes (e.g. move stock internally to a different bay, assign a new supervisor to a particular bay) that you expect will help you achieve your targets. Without IOT you would have zero visibility on your progress to achieving your targets unless you organised another manual audit which would only give a snapshot in time. With IOT you and the supervisors responsible for your loading bays can have complete visibility and transparency on loading bay performance. This continuous stream of data makes it easy to see the impact of your changes, showing you when you are doing a good job and when you are off track.

We recommend that you give full access of performance data to your managers and review on a regular basis.

Five simple steps, remember KBBTT:

KPIs: Choose your KPIs: productivity, utilisation, and bay turns

Baseline: Use connected bays to record performance data for at least 1 month

Benchmark: Using baseline data find benchmarks for superior performance

Target: Using benchmarks set targets with your loading bay supervisors

Track: Through visibility and transparency you and your bay supervisors can track performance

Conclusion

IoT technologies have emerged and transformed the landscape of warehousing and logistics due to the advantages they present within such contexts. Yet their application and use at the loading bay area remains limited. This lack of data around loading bay activities is essential as it can often result in downtime and unnecessary costs for the warehouse. By merely following five simple steps – KBBTT – any business can use IoT to shape their strategy, set effective KPIs to optimise performance, and remain competitive and profitable

Author: Castell Safety

Castell Safety believes everyone has the right to be safe at work. Castell provides sequenced process safety and efficiency solutions to the logistics and energy industries.