Optimise Supply Chain With Nearshore Manufacturing Solutions

Are you looking to streamline your business operations and cut down on costs? Opting for nearshore manufacturing solutions could be a game-changer for your supply chain. Let’s explore how moving your production closer to home can boost efficiency and save you money, all while keeping quality at its peak.

The Appeal of Nearshore Manufacturing

Nearshore manufacturing involves relocating your manufacturing operations to countries that are geographically close to your main operations but not necessarily within the same country. This strategy is designed to reduce costs, improve agility, and enhance the overall efficiency of your supply chain.

Here’s why it’s becoming a popular choice among savvy businesses:

Cuts Transportation Costs and Times

You’ll see immediate benefits when you shift part of your production to a nearshore location. Primarily, the reduced distance your products need to travel means you’ll spend less on shipping costs. This isn’t just about saving money; it’s about speeding up delivery times too. You can respond faster to market changes and customer demands, which is crucial in today’s fast-paced market.

Enhances Supply Chain Visibility

Nearshoring gives you a clearer view of your supply chain. By bringing operations closer to your base, you’ll gain better control and oversight. This proximity allows for more frequent visits and tighter integration with your manufacturing teams. As a result, you’ll see improved quality control and quicker response times to any production issues.

Expands Access to Skilled Labour

Many nearshore destinations boast a rich pool of skilled labour, which means you won’t have to compromise on the quality of your products. These regions often have specialised expertise in various manufacturing sectors. This ensures you have access to top-tier talent and innovative manufacturing techniques.

Simplifies Regulatory Compliance

Working with nearshore partners can ease the complexities of regulatory compliance. Neighbouring countries often establish trade agreements that facilitate smoother business operations and reduce tariffs. This setup simplifies the legal processes involved in international trade, making it easier to comply with trade laws.

If you’re based in the United States and looking for a convenient turnkey solution, working with companies like BF&S Manufacturing, which has facilities in Mexico, can be a practical approach. These firms can support your supply chain needs while adhering to high standards.

Implementing Nearshore Manufacturing

If you prefer not to partner with established firms in nearshore locations, know that adopting nearshore manufacturing requires strategic planning and careful execution. Here are some pointers to help you set up your nearshore operations for success.

Select the Right Region

When choosing a country, consider factors such as political stability, economic conditions, and local industry expertise. Countries with strong trade ties to your home base are often the best choices, as they likely offer smoother logistics and more robust legal frameworks for business.

Partner Wisely

Once you’ve chosen a region, selecting the right local partners is key. Look for manufacturers with a proven track record and robust operational frameworks. Don’t shy away from visiting potential partners to get a firsthand look at their operations. Remember, a trustworthy partner is worth their weight in gold.

Integrate Technology

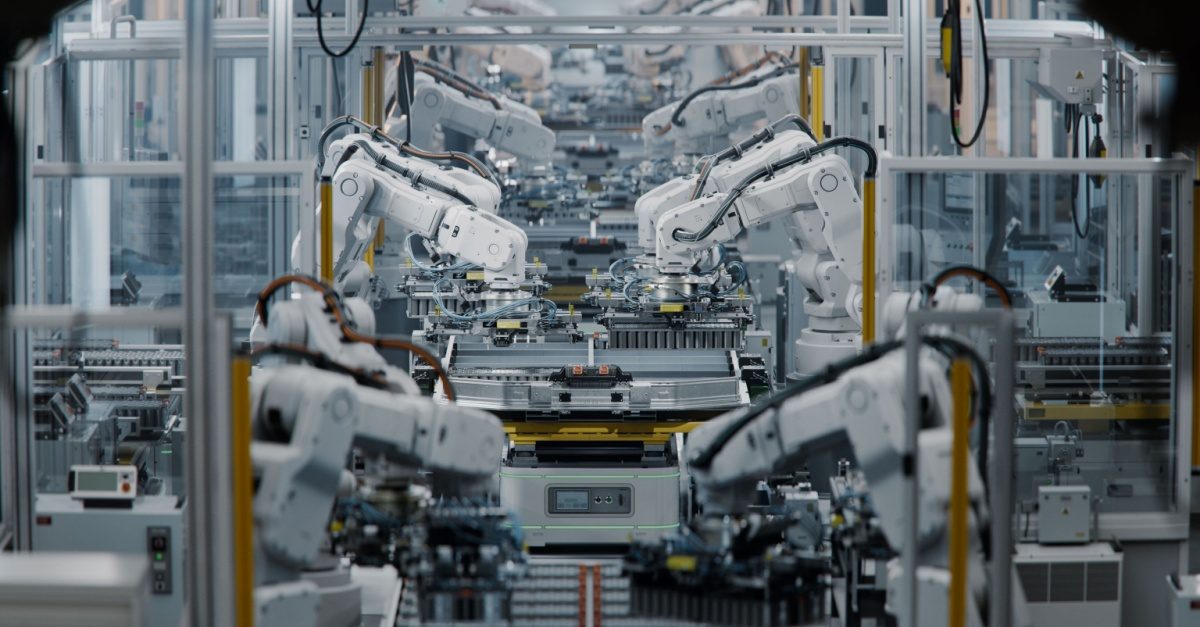

To truly optimise your nearshore operations, utilising automated systems is a must. For example, consider investing in supply chain management software that offers real-time data across all your locations. This will help you monitor every aspect of the production cycle and make informed decisions quickly.

Implementing nearshore manufacturing can significantly enhance your supply chain’s responsiveness and efficiency. With the right partnerships and technological support, you can create a seamless and robust manufacturing network that drives business growth.

The Challenges of Nearshoring

While nearshoring offers numerous advantages, it also presents unique challenges that require thoughtful management. Addressing these issues promptly contributes to smoother transitions and successful integration into new markets.

Managing Cultural Differences

While nearshore regions may be geographically close, cultural differences can still pose challenges. Understanding and respecting local customs and business practices is key to facilitating smooth operations. This might require adjustments in your communication styles or negotiation techniques.

Overcoming Initial Setup Costs

Setting up operations in a new location requires upfront investment. You’ll face costs associated with establishing facilities, training staff, and integrating systems. However, the long-term savings and operational benefits can far outweigh these initial expenses.

Despite the challenges, the strategic benefits of nearshoring can decisively outweigh the initial difficulties. With careful planning and effective management, these obstacles can be transformed into opportunities for growth and innovation.

Wrapping Up

Nearshore manufacturing offers compelling advantages for your supply chain, from cost savings and improved efficiency to better quality control. It’s a cost-effective approach that allows you to stay agile in a competitive market and respond more effectively to consumer demands. With the right planning and partnerships, you’re well-positioned to transform your supply chain into a dynamic asset that enhances your business’s resilience and profitability.