Maximise Assembly Line Automation Efficiency

Maximising efficiency is more than just a goal—it’s essential for staying competitive in the manufacturing industry. Assembly line automation has become a key driver for improving productivity, reducing errors, and maintaining consistent quality. However, achieving optimal efficiency requires continuous upgrades and improvements. Whether you’re just starting to automate or looking to enhance an existing system, focusing on specific areas can greatly increase your assembly line’s output and reliability. Here’s a guide to the essential upgrades you can make to take your assembly line automation to the next level.

1. High-Quality Bearings

Bearings play a critical role in supporting and reducing friction in various moving parts of an assembly line. High-quality bearings, such as those from Lily Bearing, can reduce wear, increase operational speed, and improve longevity, all of which are crucial for efficiency. Investing in reliable bearings can help prevent costly downtime and maintenance.

2. Enhanced Conveyor Systems

Efficient conveyor systems streamline product movement through different assembly stages. Upgrading to conveyors with advanced motors and adjustable speeds ensures smooth transitions, minimising delays and bottlenecks along the line. Enhanced conveyor systems with smart sensors can detect and respond to varying load capacities, adjusting speed and flow dynamically to optimise efficiency and reduce energy consumption.

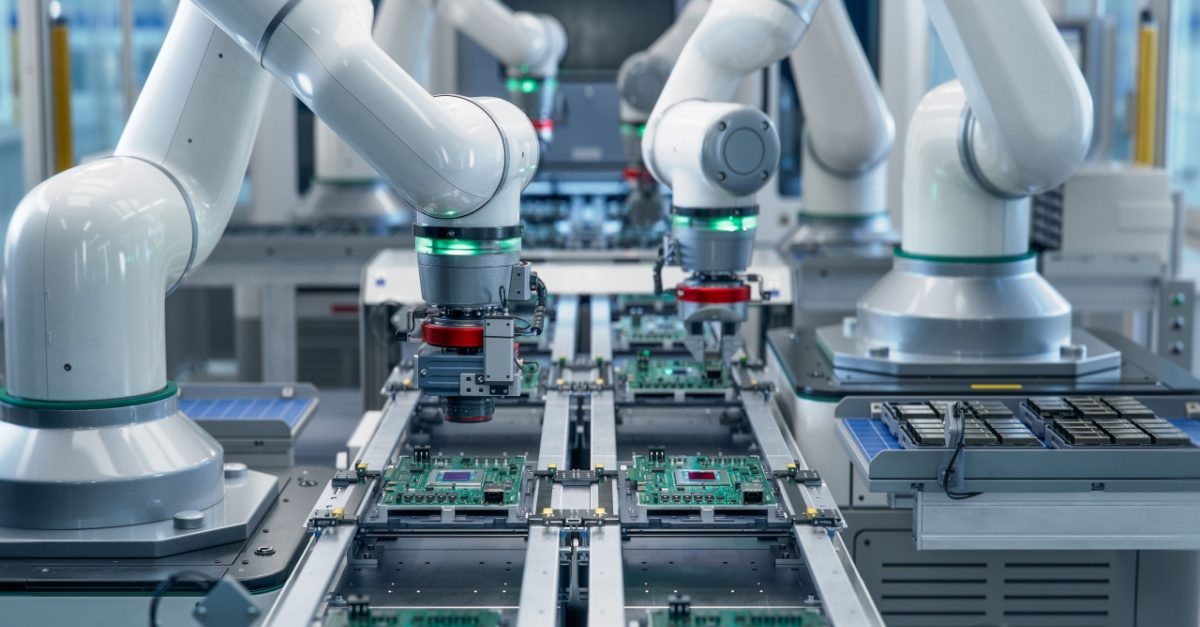

3. Advanced Robotic Arms

Robotic arms have evolved significantly, with newer models offering improved speed, precision, and versatility. Adding high-performance robotic arms to your assembly line can increase output, reduce human error, and ensure precise handling of materials. Advanced robotic arms equipped with AI-powered vision systems can adapt to diverse tasks and complex shapes, making them ideal for handling intricate components and enhancing overall production flexibility.

4. Automated Quality Inspection Systems

Quality control is essential in automated assembly lines, and automated inspection systems can detect defects faster than human inspectors. Using vision systems with AI-driven analysis helps maintain quality standards without slowing down production. For instance, in electronics manufacturing, automated quality inspection systems can identify tiny soldering defects on circuit boards, ensuring high product reliability and reducing the risk of costly recalls.

5. Programmable Logic Controllers (PLCs)

PLCs are the backbone of automated systems, controlling machinery and processes in real time. Upgrading to the latest PLCs with advanced programming capabilities allows for greater customisation, faster response times, and better integration with other automated components.

6. Smart Sensors for Real-Time Monitoring

Smart sensors track performance metrics such as temperature, pressure, and vibration, enabling real-time monitoring of machinery. This data helps in identifying inefficiencies and signs of wear, allowing for timely maintenance and adjustments. For example, in food processing, smart sensors can monitor temperature and humidity levels, ensuring optimal conditions for product quality and safety while immediately alerting operators to any deviations.

7. High-Speed Cameras for Troubleshooting

High-speed cameras allow for detailed analysis of the production line, making it easier to spot and diagnose issues as they happen. This upgrade is especially useful in high-speed operations where problems can occur quickly. For example, in bottling plants, high-speed cameras can capture detailed footage of misalignments or blockages, enabling quick adjustments to prevent costly downtime and product loss.

8. Precision Laser Cutting and Welding

Precision laser equipment offers a high level of accuracy and consistency in cutting and welding tasks. Upgrading to laser-based systems can reduce material waste, improve quality, and speed up certain assembly stages. For instance, in automotive manufacturing, precision laser cutting allows for the exact fitting of metal components, ensuring stronger welds and reducing the need for rework, which enhances both durability and production speed.

9. Collaborative Robots (Cobots)

Unlike traditional robots, cobots work safely alongside human operators. Adding cobots can be a game-changer for tasks that require both automation and human supervision, enhancing productivity without compromising safety. For example, in electronics assembly, cobots can handle repetitive tasks like placing components, while human operators manage quality control, creating a seamless workflow that boosts efficiency and maintains high standards.

10. Integrated Data Analytics

The most popular recent software purchase among U.S. manufacturers was business intelligence and data analytics software, with 79% of companies opting for this investment. Data analytics software helps track production metrics and identify inefficiencies. Integrated analytics tools provide insights into performance, enabling managers to make data-driven adjustments to the assembly process. For instance, in pharmaceutical manufacturing, integrated data analytics can monitor equipment performance and predict maintenance needs, helping to prevent unexpected downtime and ensure consistent product quality.

11. Automated Packaging Systems

Automated packaging saves time by handling products at the end of the assembly line. These systems can be customised for different packaging needs and work in sync with the rest of the assembly line, providing a seamless transition from production to shipping.

Final Thoughts

Maximising efficiency in assembly line automation requires targeted upgrades that not only enhance performance but also reduce downtime and operational costs. From precision components like high-quality bearings to advanced software and data analytics, each upgrade plays a critical role in streamlining the process. As automation technology continues to evolve, investing in these key areas will help your business stay competitive, flexible, and ready to meet the demands of modern manufacturing. By making smart choices today, you’re setting your assembly line up for success well into the future.

At the Institute of Supply Chain Management (IoSCM), we create confident manufacturing and production planners and managers with a range of bespoke manufacturing courses. Our unique and innovative training courses allow each learner to use their practical work experience to help earn an accredited industry-recognised qualification. From introductory production planning and scheduling training to advanced types of manufacturing operations, the IoSCM Manufacturing and Production Academy offers manufacturing qualifications from Level 2 to Level 7. Call 0800 1422 522 today to speak with a Course Advisor about which level and qualification is most beneficial for you and your wider team.