Digital Tools and Their Transformative Impact on Supply Chain Management

Digital transformation might sound futuristic but in reality, it’s becoming a synonym for a successful business. It’s the natural progression of technology that brings us lower costs in production and better efficiency. A recent survey conducted by McKinsey revealed that companies fully embracing change in their supply chain operations could potentially slash inventory costs by up to 20%, reduce logistics expenses by 15%, and enhance supply chain flexibility by 50%. This survey underscores the importance of tools for streamlining supply chain operations. With that enthusiastic thought, we’ll explore the impact of these digital tools and their roles in streamlining processes, enhancing collaboration, managing risks, and preparing for future challenges.

By understanding and leveraging these technologies, you can build resilient, efficient, and sustainable supply chains ready to meet the demands of the modern marketplace.

The Evolution of Digital Tools in Supply Chain Management

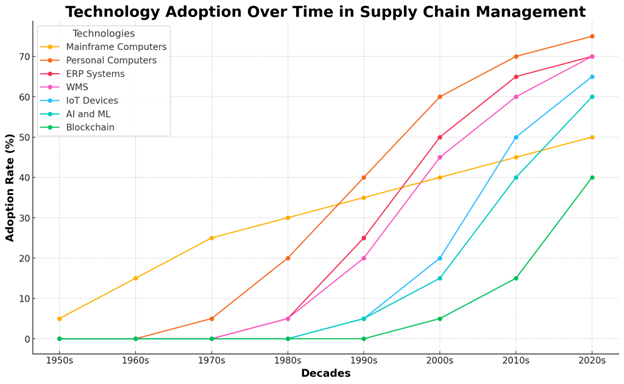

Early Developments in Supply Chain Management (1950s-1970s)

Supply chain management (SCM) has undergone significant transformations over the last few decades as technology has advanced. If we look at traditional SCM methods, we see manual, paper-based processes that always rely on human employees for various tasks such as inventory tracking, order processing, and logistics management. Communication within this supply chain was sluggish, resulting in delays and inefficiencies.

People lacked real-time data and that always means it’s almost impossible to adapt to changes quickly.

The Rise of Personal Computers and ERP Systems (1980s-1990s)

The true digital revolution in CSM started in the late 20th and early 21st centuries with the introduction and mass usage of the internet and personal computers. One of the earliest and possibly the most transformative breakthroughs was the creation of Enterprise Resource Planning (ERP) systems. The idea was to integrate business processes, including procurement, production, and distribution into one comprehensive platform.

Warehouse Management Systems (WMS) also came into the picture of tool advancements during this period, transforming inventory management practices. WMS introduced automation to warehouse tasks boosting efficiency in activities like picking, packing, and shipping.

The Internet Age and the Emergence of IoT (the 2000s)

The early 2000s marked the dawn of the Internet age, which brought unprecedented connectivity and data-sharing capabilities. This was a moment when The Internet of Things (IoT) had a major role to play in SCM, enabling real-time monitoring and tracking of assets. IoT devices, such as sensors and RFID tags, provided better visibility into the supply chain, allowing precise inventory management and predictive maintenance.

Separately, we saw the emergence of cloud-based software that made it easier for businesses to have all their systems talk to each other. This has been particularly useful for non-enterprise businesses that don’t require an ERP. Instead, a cloud-based accounting system can act as the source of truth with integrations to e-commerce/POS systems, inventory management systems and shipping/logistics software.

The AI and Machine Learning Revolution (2010s)

The 2010s saw the rise of Artificial Intelligence (AI) in business and Machine Learning (ML) as new, optimised, and transformative forces in SCM. AI and ML technologies enabled advanced data analytics, providing insights that were previously unattainable. These tools could use the data to forecast demand, optimise inventory levels, and detect anomalies in real-time, allowing for proactive rather than reactive decision-making.

Blockchain and Enhanced Transparency (Late 2010s-Present)

Moving into the 2010s and beyond blockchain technology offered decentralised and tamper-proof ledger systems, ensuring that every transaction within the supply chain was recorded and verified. This innovation enhanced traceability, improved security, and helped prevent fraud.

Sources: McKinsey & Company, Gartner, World Economic Forum

Impact of Digital Tools on Efficiency and Productivity in SCM

Moving on from statistical data to more tangible and real-world examples, let’s take a closer look at how digital tools influence supply chain management in every way that matters:

Streamlined Operations and Reduced Manual Intervention

Digital tools have enhanced efficiency and productivity in SCM by minimising the need for human intervention and streamlining operations. Automation tools like ERP and WMS handle repetitive tasks such as order processing, inventory management, and shipment tracking, allowing employees to focus on more strategic activities.

For example, robotic process automation (RPA) in warehouses can perform picking, packing, and sorting faster and more accurately than humans. Using technology can speed up tasks, minimise mistakes, and cut down on expenses, ultimately boosting productivity.

- Tip: If you want to see the results first-hand and use the technology to your advantage start by evaluating existing supply chain processes. This will help pinpoint areas where digital tools can make the enhancements. It’s a good idea to develop a digital transformation roadmap with clear objectives and a phased implementation plan.

Increased Accuracy and Reduced Errors

Digital tools enhance the accuracy of supply chain operations by automating data collection and processing.

Technologies such as RFID and barcode scanning ensure precise inventory tracking, while AI and machine learning algorithms analyse large datasets to detect patterns and anomalies. This results in demand forecasting, optimised inventory management, and early detection of potential issues.

Furthermore, blockchain technology contributes a layer of accuracy by creating a transparent transaction record that minimises fraud risks while ensuring data integrity throughout the supply chain.

Enhanced Collaboration Across the Supply Chain

Digital tools also promote better communication and collaboration because they offer real-time data sharing.

Platforms like collaborative planning, forecasting, and replenishment (CPFR) systems allow companies to share forecasts, production plans, and inventory levels, aligning their operations to meet demand more effectively. Additionally, cloud-based supply chain management systems provide an online hub for controlling and monitoring supply chain operations, keeping all stakeholders informed of any changes or interruptions.

One significant advantage of these tools is making pipeline generation easier in supply chain management. Pipeline generation is the continuous flow of products and information through the supply chain. By providing real-time visibility and analytics, digital tools enable companies to manage and optimise their supply chains more effectively, ensuring a steady flow of goods and data. This continuous flow helps meet customer demand more efficiently and maintain a competitive edge.

- Tip: Use the technology to connect people rather than relying on it simply for repetitive tasks. Promote digital literacy and create a culture that embraces digital innovation by pointing out the benefits and showing all stakeholders that collaboration is key to making their lives easier.

Using Digital Tools for Enhancing Visibility and Transparency

Real-time Data Sharing Across Multiple Locations

Real-time tracking technologies and comprehensive data analytics offer a bird’s-eye view of the entire supply chain, providing insights that were once hidden by the fog of manual processes and delayed communications.

Website screenshotting technologies, for instance, allow businesses to capture and archive real-time snapshots of online transactions, inventory levels, and even supplier websites, providing a clear picture of operations at any given moment. This seemingly simple capability can be particularly beneficial in scenarios where information verification or historical data comparison is required.

Advanced tracking systems, powered by GPS and IoT devices, further enhance visibility by allowing companies to monitor the exact location and condition of their goods throughout the transportation process. This real-time data is invaluable in reducing the anxiety of unknowns, ensuring stakeholders are always aware of where their products are and when they can expect delivery.

Improved Supplier and Customer Relationships

Visibility and transparency strengthen relationships with suppliers and customers. Real-time data sharing and dispatch software ensures suppliers know about demand fluctuations and production schedules, enabling them to adjust their operations accordingly. Similarly, customers benefit from improved service levels and timely updates on order status.

A great example of enhancing visibility and transparency is the use of digital tools to manage numerous locations on GMB. By integrating real-time data sharing and analytics, you can provide accurate and up-to-date information about locations, products, and services. This improves the customer experience and also helps in managing and optimising operations across various locations. For example, a retailer with multiple locations can use these tools to track inventory levels, monitor sales performance, and ensure consistent service quality across all locations.

Risk Management and Resilience with Digital Tools in SCM

The usefulness of digital tools doesn’t stop at boosting efficacy, productivity, and communication. You can also count on the amazing data-collecting and processing powers of these tools to manage risks and build resilience.

AI and machine learning algorithms can analyse historical data and identify potential risks such as supply shortages, demand fluctuations, and logistical challenges in a way humans never could. By foreseeing these risks, companies can take steps to mitigate them, such as diversifying suppliers, adjusting inventory levels, and optimising transportation routes.

Building Resilient Supply Chains with Digital Tools

Building resilient supply chains is essential. Digital tools enable companies to create flexible and adaptable supply chains that can withstand disruptions.

For example, IoT devices provide real-time monitoring of assets, allowing companies to respond quickly to any issues. Blockchain technology ensures transparency and traceability, making it easier to track and resolve problems. By leveraging these tools, companies can enhance their resilience and ensure continuity of operations.

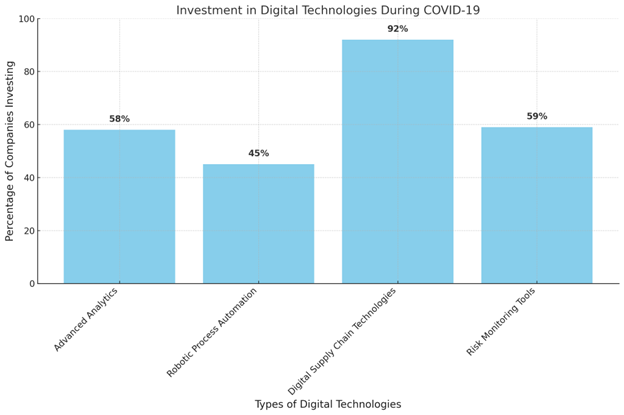

The Role of Digital Tools in Crisis Management and Recovery

In times of crisis, digital tools are extremely useful for managing and recovering from disruptions.

During the COVID-19 pandemic, many companies relied on digital tools to maintain operations despite worldwide disruptions. For example, remote project management tools allowed companies to oversee their supply chains from afar, while AI-driven analytics helped them adjust to changing market conditions. By providing the flexibility and agility needed to overcome crises, digital tools help companies recover faster and emerge stronger.

Source: McKinsey & Company, EY US, World Economic Forum

Sustainability and Environmental Impact of Digital Tools

Digital tools are good for successful companies and amazing for clients, but they also contribute to sustainability ideology and make the world a better, cleaner place.

Reducing Waste and Improving Resource Utilisation

Digital tools contribute to sustainability by reducing waste and improving resource utilisation. IoT sensors and AI-driven analytics can optimise energy usage, reduce emissions, and minimise waste in production and logistics processes.

For example, predictive maintenance systems use IoT data to monitor equipment health and schedule maintenance before breakdowns occur, reducing downtime and resource waste.

Enhancing Sustainability Through Digital Transformation

The digital transformation of supply chains enhances sustainability by enabling more efficient and eco-friendly procurement practices. Blockchain technology ensures product traceability, allowing companies to verify the sustainability of their supply chains and comply with regulatory requirements.

Additionally, advanced planning and scheduling tools help companies optimise production and logistics, reducing their operations’ environmental impact.

Emerging Trends and Future Outlook

The future of supply chain management is being influenced by a variety of developments. Advanced robotics, autonomous vehicles, and drones are transforming the way logistics and transportation operate. AI is being used to improve analytics and automation capabilities. Additionally, blockchain technology is increasing transparency and security, within supply chains while IoT devices are offering real-time data insights.

Final Thoughts on the Impact of Digital Tools

The use of tools has significantly changed the way supply chain management operates leading to improvements in efficiency, accuracy, collaboration, and resilience. From the days of ERP and WMS to the innovations in AI, IoT, and blockchain, these technologies have completely transformed all aspects of supply chain operations.

Companies that adopt transformation can streamline their processes, cut expenses, promote sustainability, and establish adaptable and resilient supply chains. History has shown us that embracing advancements is more beneficial than sticking to our comfort zones. Therefore, integrating technologies into supply chain strategies is the next step for companies looking to evolve and thrive in a dynamic business environment.

Author Name — Ahmad Benny

Bio — Ahmad Benny is the Founder of Bengu, a site that helps marketing teams cut through the noise on B2B SAAS software to help them make an informed buying decision. On the site, you can find expert-led reviews and how-to guides on a variety of marketing topics.

Guarantee success in your supply chain with IoSCM. Find out how our qualifications, resources, support and expertise can help you. Call 0800 1422 522 today.