For effective procurement of the parts, products and services your business needs, you need to ensure supply chain analytics are a key priority.

The supply chain is an important piece of the puzzle for business success since it directly influences a company’s capacity to create a great customer experience while also accounting for many of the expenses that affect overall profitability. The supply chain is a network that connects suppliers, businesses, and end users, and it includes everything from raw material procurement to delivery to the ultimate consumer.

Given the supply chain’s critical relevance to businesses, many have increased their supply chain management (SCM) efforts. They’re searching for ways to make procedures faster, cheaper, and easier throughout the long path from a raw materials supplier to the end user. This is especially important because supply chains have gotten increasingly complex over time—companies engage with an increasing number of overseas partners and face increasing pressure to produce their products as promptly as feasible.

A vast range of activities, individuals, and organisations are involved in supply chains, resulting in a massive amount of data. This is where supply chain analytics come in—they can transform that massive quantity of data into easily accessible dashboards, reports, and visualisations that affect important choices and lead to better results. In an increasingly competitive world, easy access to these analytics has become important.

What Is the Role of Supply Chain Analytics?

Supply chain analytics enables businesses to collect, analyse, and act on data created by their supply chains. It enables them to make not only short-term adjustments but also long-term strategic improvements that will provide the company with a competitive advantage. Because supply networks frequently span the world and can include hundreds of different companies, manually or via spreadsheets, organising this information is nearly impossible.

Demand forecasting (using historical data and other factors to estimate what consumers will order); sales and operations planning (producing and/or acquiring the commodities a business needs to satisfy forecasted demand); and inventory management are a few examples of supply chain analytics (tracking sell-through of items and which SKUs it needs to replenish). Each of these tasks has the potential to increase the overall efficiency of corporate operations and result in significant cost savings. For example, more accurate demand planning implies reducing procurement expenditures while also preventing stockouts and surplus inventory (which can turn into obsolete inventory). So, your company is cutting costs while still providing an excellent client experience, which will help you stand out from the competitors.

Supply chain analytics is becoming increasingly vital in today’s most successful companies’ day-to-day operations. Organisations are paying more attention to these numbers than ever before, and numerous analytics tools are being used to enhance each link in this network.

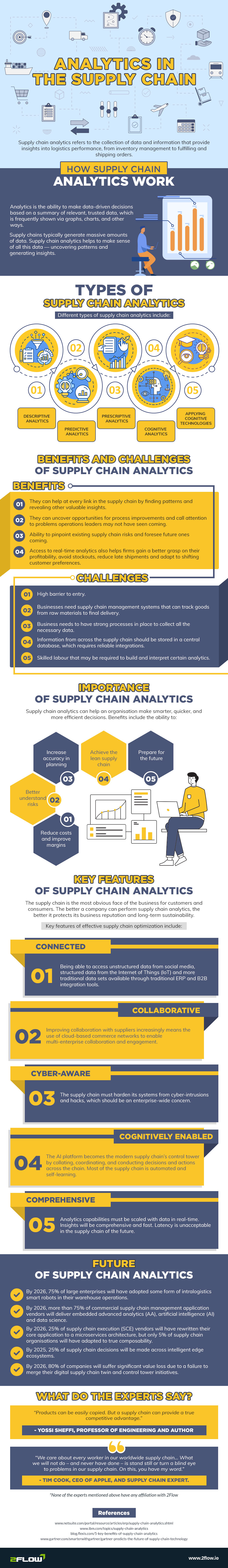

Check out the infographic below by warehouse and logistics experts 2Flow which takes a further look at ‘Analytics In The Supply Chain’.

Supply Chain analytics are one great way to advance your business operations. Upskilling your team is another! IoSCM can advance the capabilities of your full team with training and development available to match the requirements of each member of your team, and the wider organisation. Speak with a Course Advisor today for further information. Call 0800 1422 522.