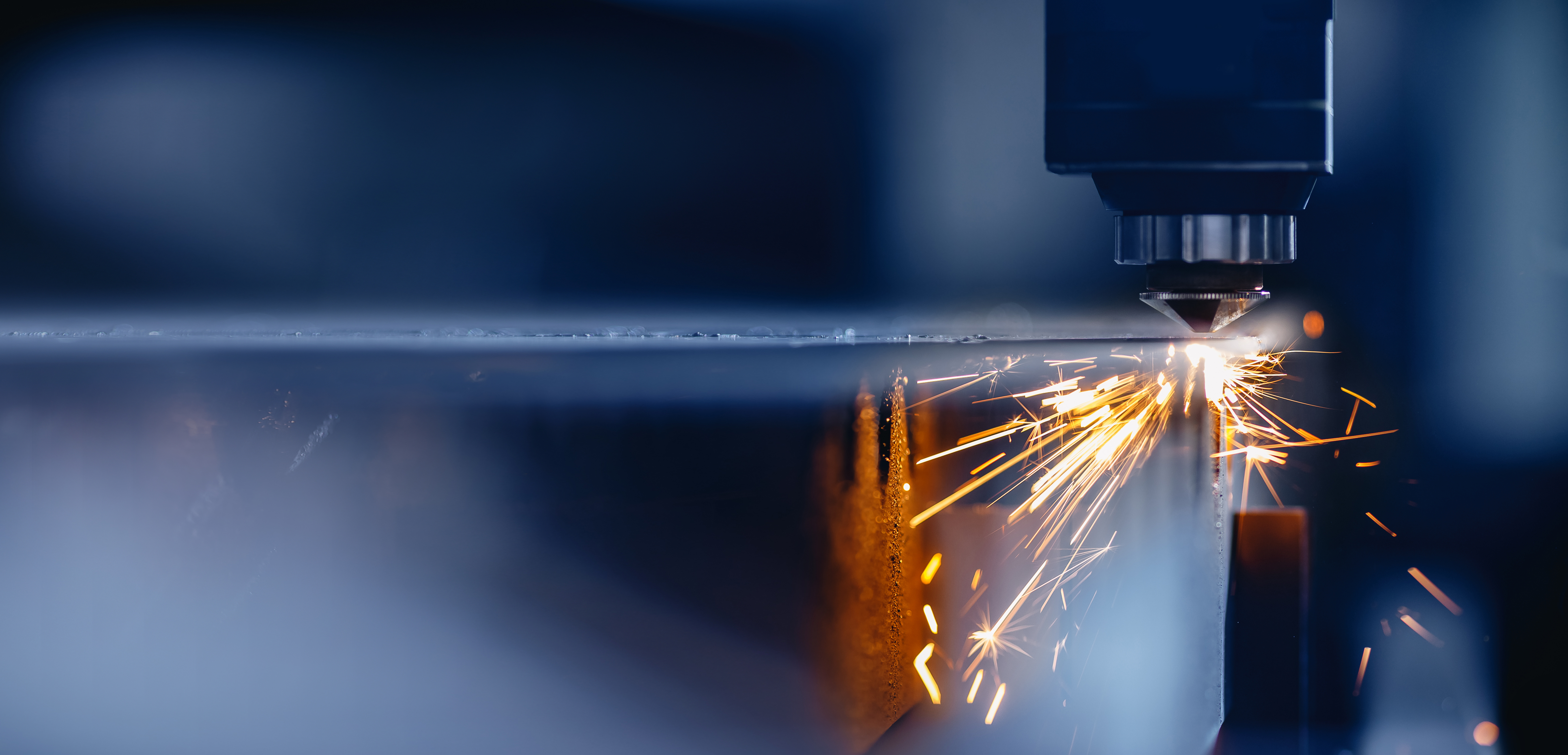

Blue color Laser CNC cut of metal with light spark, technology modern industrial.

Industrial machinery is one of the costliest investments for companies, so proper maintenance is key to get the highest possible value of your purchase. Besides, if your equipment breaks down due to lack of maintenance, it may delay or stop work for the whole construction site, costing your company a fortune.

A simple way to protect your investment and avoid expensive breakdowns is to know how to maintain your industrial equipment properly. With correct maintenance, you won’t only extend the lifespan of your equipment, but you can also save your money and time.

Regardless of what type of industrial equipment you own, below are some of the tips you should take into consideration:

Implement A Maintenance Routine

One of the first tips to care for your industrial equipment is to establish a regular maintenance routine. Every piece of equipment must be checked on frequently to watch for problems such as lack of coolant supply, broken or missing teeth on the cutting edges of the attachments, proper tire inflation, fluid levels, and fluid line leakage.

Regular maintenance needs like new brakes or oil change must be performed based on the specifications of the manufacturers. By scheduling repairs as early as possible, you can rest assured that your industrial equipment will avoid any possible problems that may result in lost productivity.

If your industrial equipment is exposed to harsh environmental conditions, you would want to adjust the manufacturer recommendations accordingly. For instance, in a workplace with lots of dust, changing the air filters may be a frequent need.

Another part of your maintenance routine is keeping your industrial equipment free of debris to help prevent corrosion and extend the equipment’s lifespan. Therefore, always pay attention to the environment and surroundings where you store your equipment

Keep An Eye Out For Wear And Tear

Each time you clean your industrial equipment, take some time to check the vital parts of the machine for possible wear and tear. Some parts wear out easily and become damaged because of regular use and may go unnoticed. For this reason, you must watch closely for various imminent issues. In addition to that, check your tires daily as it takes several minutes and may save you more money in purchasing new tires. The goal is to repair the small problems before they become more serious issues and affect your company’s supply chain.

Follow Manufacturer Recommendations

Another tip for maintaining your industrial equipment is to follow the maintenance recommendations of the manufacturer. Taking care of your industrial equipment while it’s in use is also essential to avoid machine failure. A good way to reduce the risk of the breakdowns is through following the guidance of the manufacturer in terms of how industrial equipment must be used.

Every piece of industrial equipment was made with a particular task in mind and to be used with specific parts and attachments. Once operators use industrial equipment for work that they’re not designed for, fix them with any inappropriate parts or use attachments that don’t fit properly, they can cause the breakdown of the machine. Following the recommendations of the manufacturer for how equipment must be repaired and used is another way to maintain your fleet properly.

You should also keep in mind that particular machines were manufactured to carry and lift a particular amount of weight and you must be aware of their limits. Exceeding the recommended specifications and limitations of your industrial equipment may compromise its effectiveness and efficiency. This may result in problems that may endanger the operator. Some of the things that may contribute to both safety and mechanical issues include inclines for transits and failing to follow the weight load limit.

Ensure Safe And Secure Storage For Your Equipment

Your industrial equipment should be stored in a dry, secure and safe location to protect it from any elements. Once you have proper storage for your equipment, it’ll be much easier for you to keep it away from direct sunlight and moisture, which reduces the risk of corrosion, degradation, and rust.

Train Your Operator For Proper Machine Operation

A well-trained operator can make a huge difference in the longevity of a certain industrial equipment. One of the reasons behind it is that they’ll know and understand the limitations and capabilities of the machine while picking up any maintenance problems immediately. The best training program for your operator must include the review of the equipment’s manual and a demo of the controls and systems. However, it may vary from one equipment to another as special certifications might be needed before operation starts.

Conclusion

Maintaining your industrial equipment can benefit your company tremendously. Implementing a regular maintenance routine, keeping an eye for wear and tear, and finding the right storage for your equipment are just some of the best tips you can consider. Just make sure to commit to these tips and be consistent with your maintenance efforts to ensure the efficiency of industrial equipment.