The Impact of Electric Vehicle Production on Global Supply Chains

The transportation industry and global supply chains couldn’t operate without each other. When one grows, the other must grow alongside it. Supply chain leaders should adapt as electric vehicle production increases for most car manufacturers. Here are a few considerable implications to discuss and manage as electric trucking upgrades become more common.

Batteries Will Challenge Supply Chain Routes

Current supply chain trucks plan routes according to their petrol tank sizes, route optimisation and the placement of petrol stations. These steps are essential when working with traditional internal combustion engines but must change when companies switch to electric trucks or delivery vans.

Each vehicle’s battery will have a different storage capacity. A standard electric transport truck gets 270 kilometres per charge and heavy goods vehicles drive around 3.8 billion tonne-kilometres annually, so their routes demand high mileage.

Supply chain teams must assess the mileage in each truck’s battery compared to their previous vehicle’s mileage to understand how many stops they’ll need to recharge on each route. Longer routes could require more shipping time if the truck requires time to charge. The specific amount will depend on the battery type.

The changing weight of each delivery will also drain an electric vehicle’s battery more or less. Optimising each route based on available charging stations and the time required for each battery will necessitate changes to long-held delivery route schedules.

It’s not an impossible challenge, but it might take some time to rework with individual delivery teams. Given how electric vehicle adoption will reach 45% of global markets by 2030–2035, accepting and unpacking each challenge is essential to maintaining industry growth within international supply chains.

Some Last-Mile Changes Will Be Necessary

The last mile of any delivery always presents a few obstacles. Drivers know to expect them but may encounter new challenges when driving electric vehicles.

First, there’s the matter of recharging after a successful delivery. Electric trucks must charge after arriving, but some areas’ charging infrastructure may remain underdeveloped. It could prevent supply chain vehicles from delivering to all the standard locations for manufacturers. Each destination’s infrastructure will rely on local government support and private investments, which may be unpredictable in some areas.

Each client’s delivery expectations may also have to shift. Some teams may have to operate with smaller electric vehicles than the diesel-burning trucks they drove before. These situations will require creativity to optimise truck storage.

Smaller, lighter trucks accommodate for batteries that can’t pull heavy freight, but they aren’t without use for companies in global supply chains. The recent £17.1 million government investment in all-terrain electric delivery vehicles will add to each industry’s existing fleets, ultimately creating new jobs and reducing the U.K.’s CO2 emissions. Additional positions and extra trucks significantly improve any company’s delivery abilities, regardless of storage capacity.

New technologies in electric vehicles also stand to support supply chain businesses.

Improvements like real-time tracking boost route optimisation and collaboration. If an electric truck ran out of battery life mid-route, the company could access the satellite-connected data provided by the smart vehicle to get the truck’s pinpointed position. Drivers wouldn’t accidentally waste time radioing for help or searching for cell service in remote areas.

There’s also the last-mile challenge of swapping drivers for some extended routes. Each driver must learn how to operate the electric truck, which requires multi-business training. Each team within a route should have the same training. Otherwise shipments may not reach all of a company’s standard delivery locations.

Training is essential to getting a good return on investment (ROI) for each truck purchase, which requires extra scheduling and work for delivery teams. However, the time spent on these sessions will be worth it. Every driver will feel empowered to participate in the electric vehicle transformation of each supply chain and remain a core part of the industry throughout their careers.

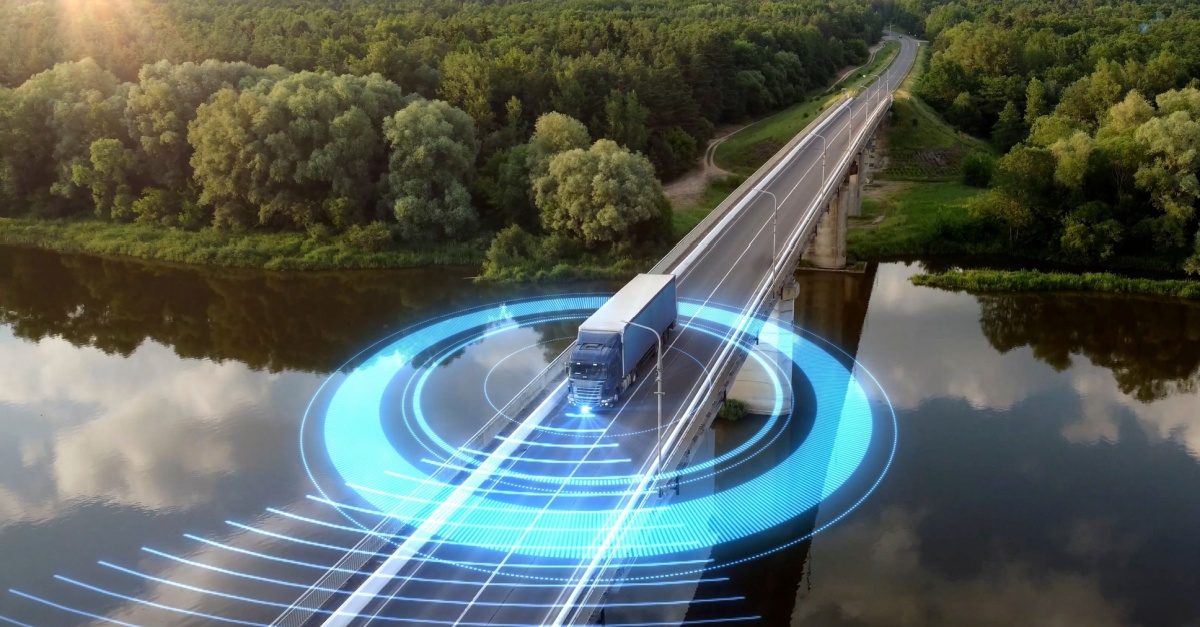

Electric Vehicle Technology Could Make Drivers Safer

Manufacturers combining electric vehicle models with new technology may include upgrades that protect supply chain drivers. An AI programme can use radars to scan the road and detect potential debris before the driver could. It would alert them so they have enough warning to slow down or change lanes, preventing accidents from sudden movements or scares.

Truck technology may also assist if the vehicles break down. They would have GPS-enabled software that better connects with satellites. Supply chain companies could automatically locate the team members needing assistance and send help without worrying about the driver not having cell service.

Prepare for Electric Vehicles in Global Supply Chains

Supply chain leaders can expect significant impacts of electric vehicle production on international industries. They’ll transform how people deliver goods, what challenges they’ll encounter along the way and the safety of each person involved. Learning about each aspect of EVs within the supply chain will help teams maintain their schedules while adapting to the changing transportation arrangements.

Author Bio

Jack Shaw, senior editor of Modded, is a respected authority on industry and business strategies. With a deep understanding of supply chains and a talent for breaking down complex concepts into easily digestible insights, Jack’s articles offer a fresh perspective on current trends and processes.